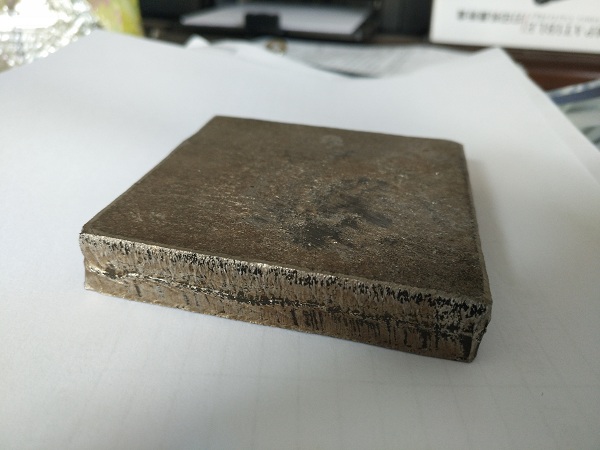

Caster chromium carbide overlay plate is a composite wear plate that comprises a base plate which has been overlaid, using open arc welding process, with our highly abrasion-resistant chromium carbide material. We also produce CCO pipe.

Delivering the high quality wear plates, we still managed to keep our costs low.

We can do this because we have developed our own flux cored wire. We can increase the chrome content to 30%-32% with our new manufacturing process.

We also offer Fabrication Services like cutting, drilling, countersunk holes, stud welding for all kinds of wear liners.

Fabrication advise:

We also produce smooth surface plate, for specific applications. max sheet size:1mx3.6m from 6+4 to 12+15.

We are expanding our smooth surface chromium carbide overlay plate production line because of growing interests in this product.

The most distinctive feature of our smooth surface bimetallic plate is that it has no weld beads. This feature makes the mirror-like smooth surface possible. As we upgraded our equipment, the process has matured.

When using traditional chromium carbide overlay plate, some material will stick to the uneven surface, causing material build-up. This problem will decrease your productivity and increase your cost. Our smooth surface wear plate is made to solve this problem. It has the combined benefits of regular-steel's smooth surface and chromium-carbide-overlay-plate's toughness. So if you have any such requirement, please tell us.

Based on submerged welding process, the chromium is overlaid on 1 pass. If you are interested in our smooth surface hardfacing plates, please contact us directly.

|

Product Name |

chromium carbide overlay plate |

|

HS Code |

8474900000 |

|

Brand |

Caster (Chinese pinyin initial: KST) |

|

Base Plate |

Q235B/SS400 |

|

Chemical Composition |

C(%): 3.0-5.0, Cr(%): 22-27, Mn(%): 2.0-3.0, |

|

Hardness |

HRC58-62 |

|

Technique |

open arc welding |

|

Wear Resistance |

30 times higher than low carbon steel and 12 times than heat treated steel. |

|

Impact Resistance |

Medium. |

|

Flatness tolerance |

±3mm/m. |

|

Thickness tolerance |

within ±0.5mm. |

|

Main Thicknesses |

4 on 6, 5 on 6, 6 on 6. 4 on 8, 5 on 8, 6 on 8, 7 on 8, 8 on 8. 4 on 10, 5 on 10, 6 on 10, 7 on 10, 8 on 10, 9 on 10, 10 on 10. 4 on 12, 5 on 12, 6 on 12, 7 on 12, 8 on 12, 9 on 12, 10 on 12, 11 on 12, 12 on 12. 4 on 14, 5 on 14, 6 on 14, 7 on 14, 8 on 14, 9 on 14, 10 on 14, 11 on 14, 12 on 14, 13 on 14, 14 on 14. 6 on 20, 8 on 20, 10 on 20…… |

|

Plate Size |

1400*3400mm |

|

Place of Origin |

China |

| Item | Hardness(HRC) | Max service temperature | Abrasion | Impact | Processibility | Service life |

| Steel plate | 35-55 | Low | ★ | ★ | ★★ | ★ |

| Hardox | 37-57 | 600 | ★★ | ★★ | ★★★ | ★★ |

| NM | 33-42 | 600 | ★★ | ★★ | ★★★ | ★★ |

| Caster wear plate | 58-62 | 600 | ★★★ | ★★★ | ★★ | ★★★★ |

Pictures of manufacturing process

Field application

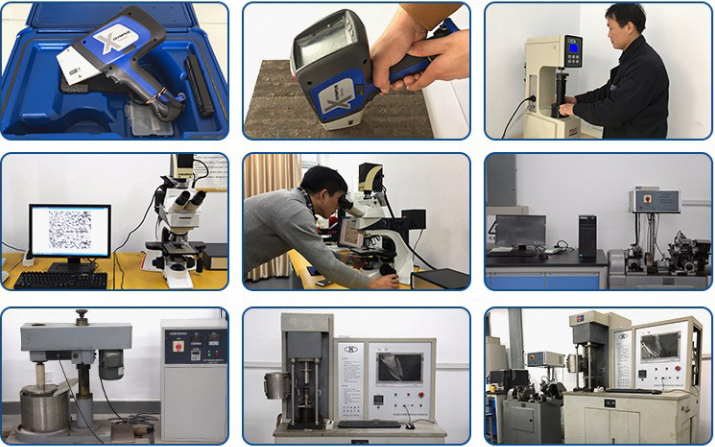

Quality inspection

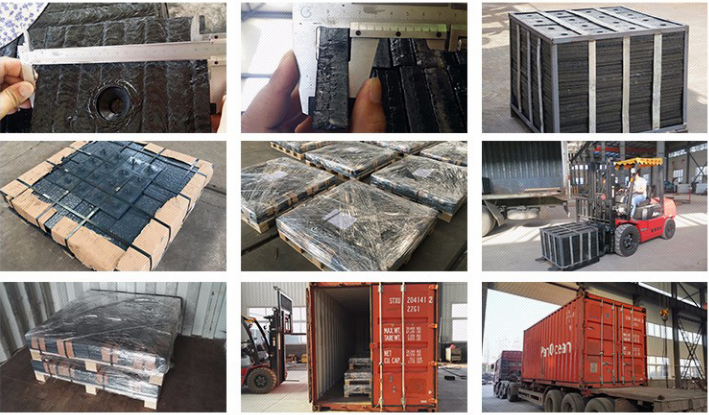

Packaging & Shipping

Packaging: Steel pallet, fumigated pallets, customised

Recommended delivery method: by sea

Production time: depend on your order quantity.

Contact: Song Binglin

Phone: +86 13801443885

Tel: 86-514-86826622

Email: jskstsbl@163.com

Add: No.100 Shuangjin Road Jiangdu District, Yangzhou City, Jiangsu Province, China